Description

Weighing system is designed for weighing of powder additives for concrete mixtures in betonárnách (such as pigments in the manufacture of stained concrete goods) or for the weighting of components for mixers in the production of building materials (such as sealants, grout, etc.)

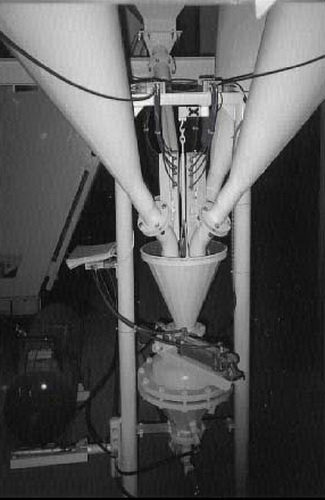

Weighing system can be used for weighing, bulk powder, a mixture of arbitrary, nelepivých media, e.g.. animal feed stuffs food stuffs (stainless steel version). The system consists of four identical pushdown units equipped with dvoustupňovými device pneumatickýmí. The receptacles are provided in the top of the hole allowing the implementation of the transport bags "big buggies". They are equipped with passive filters for the cleaning of air mass and air excessively vibrating units. Lunges from the feeders are the ventilation plant room receives the navažovacího node consisting of a support frame, solid feeder with Hopper and hung tenzometrickém sensors power. Hopper is terminated by a closing device with pneumatic control, which at the same time closing the entrance to the Chamber and feeders.

The space between the device and the top edge of the hopper is sealed using a cloth cover to prevent the leakage of controlled substances of fine particles into the surrounding space. Storage units are placed on the supporting frame design of bearing two pochůznými platforms, used also for storage transport frames with hanging through the bags. Chamber feeder is equipped with a system of internal nozzles connected via pneumatically controlled valve to stock air eliminators. Output is via a flexible member connected to the transport pipeline. Piping and discharge Sockets run into the mixer is the output work to ensure that the whole batch was transported directly to the navážená mixed with the minimum possible losses.

Weighing system is also equipped with a device for cleaning in case of changes to the navažovaných component. This device consists of a separate tank for the storage of cleaning media with pneumatic feeder. It is saved on the structure along with zásobníkovými units. Part of the delivery system are also transport frames for handling bags.

Weighing and dosing system is equipped with a separate control electronic unit, which can be operated from either the front panel or from the management console in the power.

The parameters of the

| Weighing range (1 lot) |

3.00 to 20.00 kg |

| Overload capacity scales |

50% of the |

| Power supply | 220 V, 50 Hz |

| Error weighting |

+-20 g |

| The repeatability of the benefits | +-20 g |

| Range of working temperatures |

-20 ° c ÷ + 50 ° c |

| Time to flush the Chamber feeder | 2 ÷ 6 min |

| Max. time weighting (3 components) |

180 s |

| Shipping time colors into the mixer |

approx. 15 s |

| Cover of el. parts of the |

IP 54 |

| Pressure and max. air consumption | 0.6 MPa, 20 m3/h |

The dosing system is made of materials relevant to the European normán. Used pneumatic components are certified by the manufacturer. Weighing sensor is certified for ingestion in the Czech Republic. Every mechanical part of the system is supplied by the manufacturer to be tested in a simulated traffic. The system is supplied in kit form and assembled at the place of installation for the customer.

Method of transport is the subject of the agreement at the conclusion of the purchase contract. During transport, it is necessary to protect the parts of the system from excessive shocks and crashes. For the storage it is necessary to ensure indoor environment with a relative humidity up to 80% and the temperature range-30 ° c ÷ + 50 ° c.

To download a prospectus in Adobe PDF format, click AVDBp 4-10